| teco code | N° cores x cross-section | cut | rolls [M] | drums [M] | Ext Ø [mm] | Weight [kg/km] |

|---|---|---|---|---|---|---|

46722 |

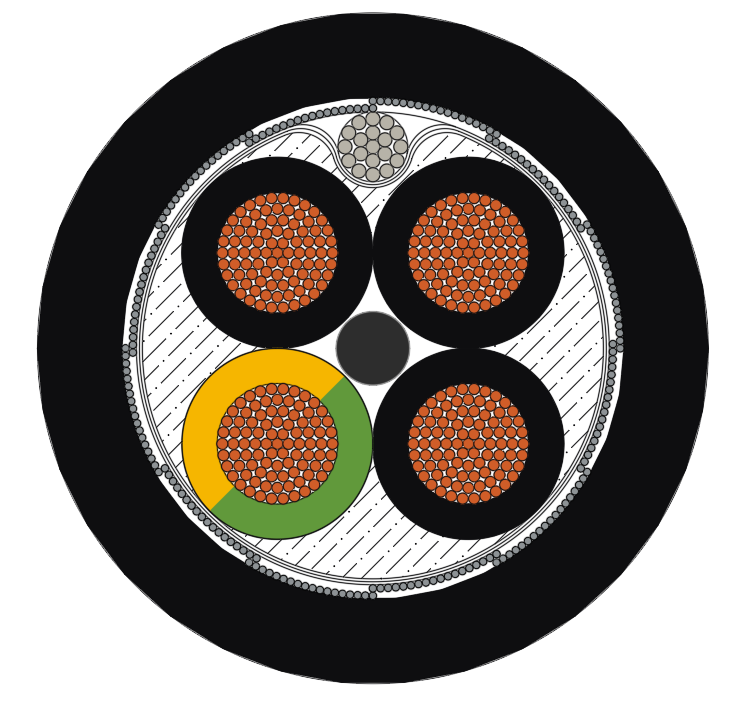

(3G1,00)ST (3GAWG18)ST |

100 |

500 |

8.1 |

93 |

|

46725 |

(4G1.50)ST (4GAWG16)ST |

100 |

500 |

9.2 |

154 |

|

46726 |

(4G2,50)ST (4GAWG14)ST |

500 |

10.5 |

210 |

||

46727 |

(4G4,00)ST (4GAWG12)ST |

500 |

11.65 |

280 |

||

46728 |

(4G6,00)ST (4GAWG10)ST |

500 |

14.9 |

445 |

||

46723 |

(5G1,00)ST (5GAWG18)ST |

100 |

500 |

9.3 |

135 |

|

46724 |

(7G1,00)ST (7GAWG18)ST |

500 |

10.1 |

165 |

||

- Cavi Speciali

RICERCA CAVO

Seleziona le caratteristiche del cavo più adatto alle tue esigenze e trova i nostri prodotti.

CAVI POSA MOBILE

Cavi certificati CE/UL/CSA per l’installazione in catena portacavi.

CAVI POSA FISSA

Cavi CE e cavi certificati UL/CSA per installazione statica.

TIPOLOGIE CAVO

Trova il tuo cavo partendo dalla tipologia di applicazione. - Passacavi

- Componenti

- Cataloghi

- Sostenibilità e Certificazioni

- Cavi Speciali

RICERCA CAVO

Seleziona le caratteristiche del cavo più adatto alle tue esigenze e trova i nostri prodotti.

CAVI POSA MOBILE

Cavi certificati CE/UL/CSA per l’installazione in catena portacavi.

CAVI POSA FISSA

Cavi CE e cavi certificati UL/CSA per installazione statica.

TIPOLOGIE CAVO

Trova il tuo cavo partendo dalla tipologia di applicazione. - Passacavi

- Componenti

- Cataloghi

- Sostenibilità e Certificazioni

Menu